In today’s rapidly evolving technological landscape, the filter cartridge winding machine has emerged as a game-changer in the manufacturing industry. This innovative machine automates and streamlines the production of filter cartridges, ensuring efficiency, precision, and cost-effectiveness.

The Advantages of Filter Cartridge Winding Machine

The filter cartridge winding machine offers numerous benefits that have revolutionized the manufacturing process. Firstly, it significantly reduces human labor by automating various stages of production. This not only improves productivity but also minimizes errors and inconsistencies in product quality.

Secondly, this advanced technology allows for precise control over critical parameters such as diameter, length, and density of wound cartridges. Manufacturers can easily adjust these settings to meet specific requirements or comply with industry standards.

Furthermore, the filter cartridge winding machine enables faster production cycles without compromising on quality. With its high-speed capabilities and efficient material utilization techniques, manufacturers can meet growing market demands while maintaining consistent product performance.

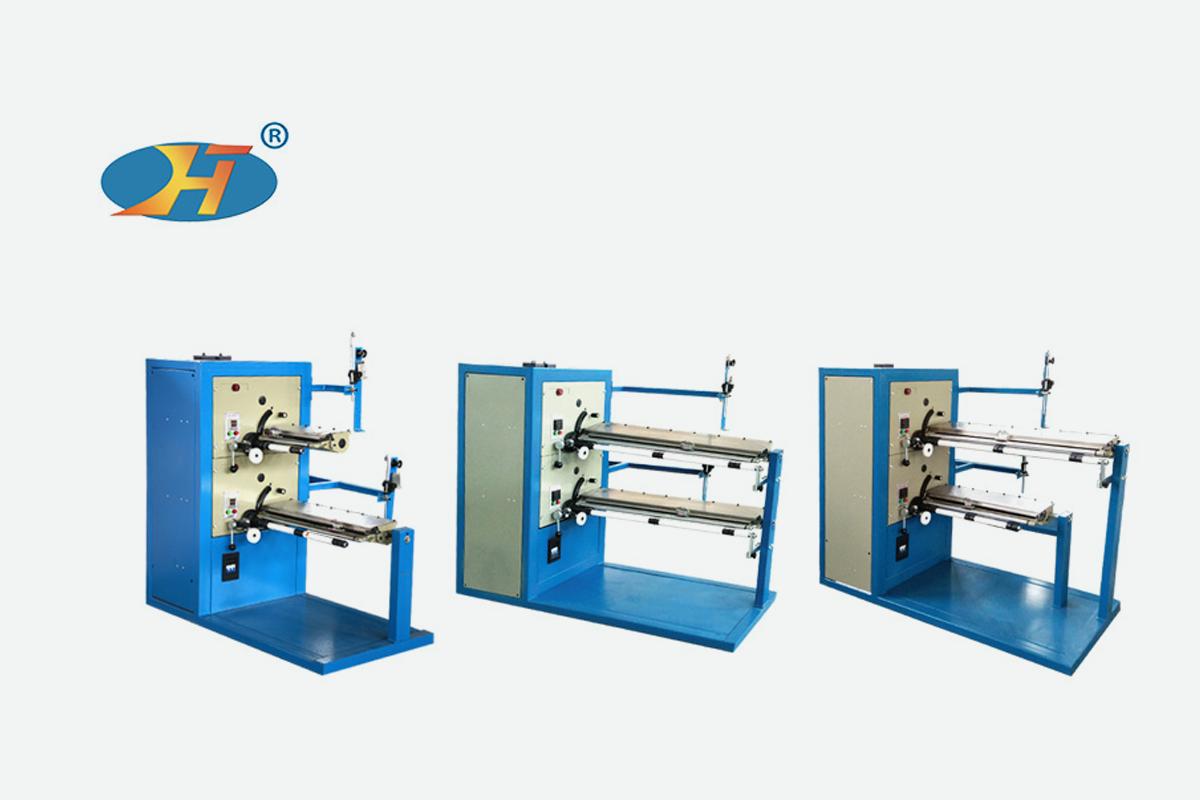

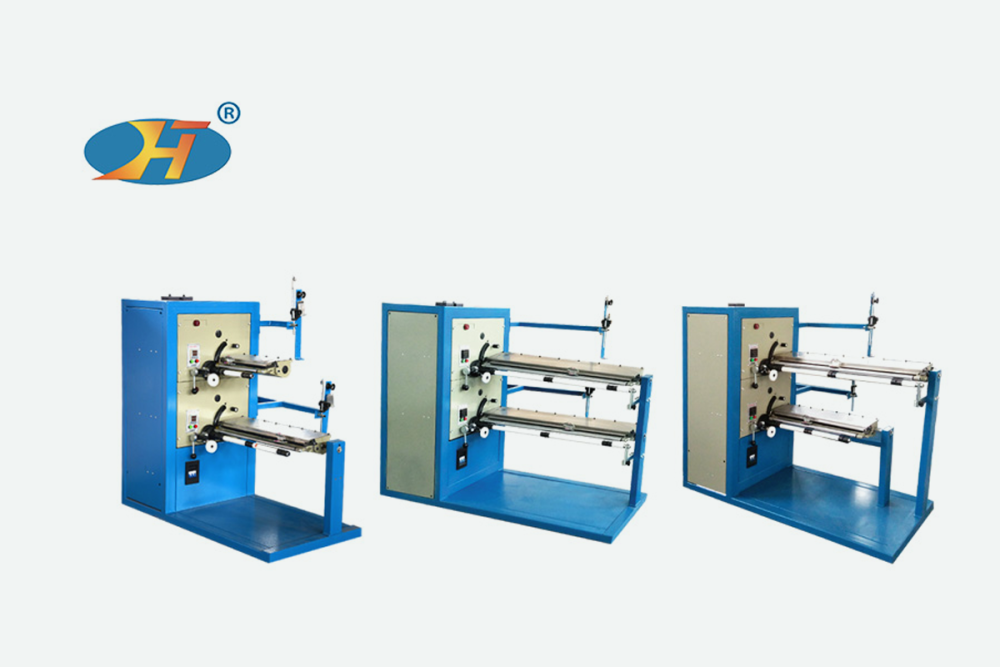

Hongteng: A Leading Innovator in Filter Cartridge Winding Machines

Hongteng is at the forefront of developing cutting-edge solutions for filter cartridge manufacturing. Their range of winding machines combines state-of-the-art technology with years of expertise to deliver exceptional results.

With Hongteng’s machines, manufacturers gain access to advanced features like automatic tension control systems and intelligent monitoring mechanisms. These ensure optimal performance throughout the entire production process while minimizing downtime due to maintenance or adjustments.

Besides their technical prowess, Hongteng also prioritizes customer satisfaction by offering comprehensive after-sales support services. They provide training programs for operators and technicians along with prompt assistance for any troubleshooting or maintenance needs.

The Impact of PP Spun Filter Manufacturing Machine

Another significant development in the filter cartridge manufacturing industry is the introduction of pp spun filter manufacturing machines. These machines specialize in producing polypropylene (PP) spun filters, which are widely used for water purification and other filtration applications.

The PP spun filter manufacturing machine ensures consistent quality by precisely controlling parameters such as temperature, pressure, and speed during the production process. This results in filters with excellent particle retention capabilities and extended service life.

Moreover, these machines offer flexibility to manufacturers by allowing them to produce filters of various sizes and specifications. This adaptability enables businesses to cater to diverse customer needs while maintaining high standards of performance.

In Conclusion

The advent of filter cartridge winding machines has revolutionized the manufacturing process by enhancing efficiency, precision, and cost-effectiveness. Companies like Hongteng have played a crucial role in driving innovation within this field through their advanced technologies and commitment to customer satisfaction. Additionally, the emergence of PP spun filter manufacturing machines has further expanded possibilities for producing high-quality filters that meet global standards. As technology continues to evolve, we can expect even more advancements in this sector that will shape the future of filtration systems worldwide.