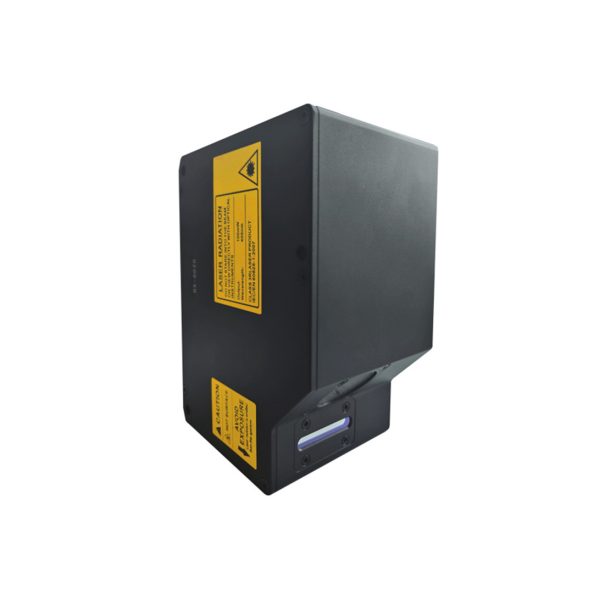

Understanding 3D Profile Sensors

3D profile sensors are advanced technological devices designed to capture and analyze the three-dimensional shapes of objects. These sensors utilize laser triangulation or structured light techniques to create detailed models, which are invaluable across various industries such as manufacturing, logistics, and quality control. By providing real-time data, these sensors enable businesses to enhance their operational efficiency and product quality. For instance, in automotive production, a 3D profile sensor can ensure that components fit perfectly, reducing assembly errors and costs. With the consistent demand for precision, leveraging 3D profile sensors becomes imperative for businesses aiming to maintain a competitive edge.

The Importance of 3D Profile Sensor ODM

The phenomenon of 3D profile sensor ODM is increasingly becoming significant in contemporary manufacturing strategies. By partnering with Original Design Manufacturers, organizations can access customized solutions that align with their specific operational needs. An example can be found in electronics assembly, where a tailored 3D profile sensor improves alignment accuracy considerably during the production line. Opting for a 3D profile sensor ODM not only enhances product reliability but also streamlines manufacturing processes, ultimately leading to reduced wasted resources and improved profit margins.

Benefits of Choosing a 3D Profile Sensor ODM

Choosing to work with a 3D profile sensor ODM provider presents numerous advantages, particularly in terms of innovation and cost-effectiveness. These partnerships allow companies to stay ahead of market trends by developing sensors that integrate the latest technologies. For instance, consider a food production company that requires sensors to maintain hygiene and product consistency. By collaborating with a skilled ODM, they can develop a bespoke solution that meets both their compliance requirements and operational guidelines. By investing in a reliable 3D profile sensor ODM, businesses not only upgrade their technological capabilities but also foster long-term supplier relationships that can lead to future innovations and improvements.

Conclusion: Why RSTC Stands Out

In summary, 3D profile sensors are transformative tools that enhance precision and efficiency in various industries. The evolving landscape of manufacturing is well-suited for the integration of customized solutions through 3D profile sensor ODM. With RSTC, enterprises benefit from their expertise in manufacturing advanced visual products, ensuring superior supply advantages and cutting-edge technology. For those looking to elevate their manufacturing processes and maintain a competitive edge, partnering with RSTC is a strategic move that promises significant returns.